What Are RFID Tags and How Do They Work?

RFID has rightfully earned its reputation as a technology for efficiently tracking large numbers of items. This capability has become increasingly important in dealing with post-COVID supply chain issues. But what is an RFID tag, and how do they work? To understand RFID tags, it is first important to understand the elements of an RFID system.

An RFID system consists of an RFID reader, software, and a tag affixed to each item. The RFID tag transmits information about the item and its location to the reader. As the item moves past the reader, the reader collects the data from the tag and reports it to the RFID software such as SML’s Clarity RFID Software . The software compiles the data and makes it available, so you know where every item is at all times. RFID tags now track everything from electronics, eyewear, and apparel.

How RFID tags work

Most RFID tags are passive, meaning that they contain no power of their own. As they pass the RFID reader, the reader’s energy activates the tag, enabling it to send its information to the reader. RFID tags can be “inlaid” or stuck to the item as a label. They can also be a hard tag made of plastic or metal affixed to the article.

Active RFID tags contain a battery that needs to be replaced every 3-5 years. These tags are great for live tracking, as in toll or cargo tracking applications. They typically have a more extended read range than passive tags, and they also tend to be more expensive.

One of the biggest factors retailers have to consider when adopting an RFID inventory management system involves selecting the size and form factor of the RFID tags.

How to select the right RFID tag form factor

Retailers gain multiple benefits from implementing RFID, including unprecedented inventory accuracy, reduced out-of-stocks, shrink reduction, sales increases, etc. However, in the past, some brands have rejected RFID systems for aesthetic reasons because they did not know how to print on the labels or tried bulky RFID tags. Clothing and accessory designers spend vast amounts of time and money creating tags, labels, and packaging that optimally represent and enhance a company’s branding. The last thing they want is to negate their hard work or be limited in their design by bulky, unflattering RFID tags.

Luckily for apparel designers, SML Inspire RFID tags have a variety of forms, and at the same time, their performance has advanced. RFID chip and tag developers are now creating small, discrete technologies that retailers can implement in inconspicuous ways that do not interfere with branding or tarnish the appeal of a product. These advancements have allowed retailers to track difficult-to-tag items such as jewellery and perfumes and increased flexibility by enabling longer read ranges.

SML RFID has designed hundreds of different inlays for businesses worldwide. This large variety of RFID tags allows retailers to track apparel, glasses, cosmetics, fragrances, accessories, and other products without negatively affecting packaging or clothing labels. We partner with the leading RFID chip suppliers to provide the smallest, most advanced RFID tags possible. These suppliers include:

Using the wide variety of available chips, SML designs high-performance inlays that meet your specific needs and perfectly match your branding. Our tags are certified to meet the performance standards your unique deployment circumstances require.

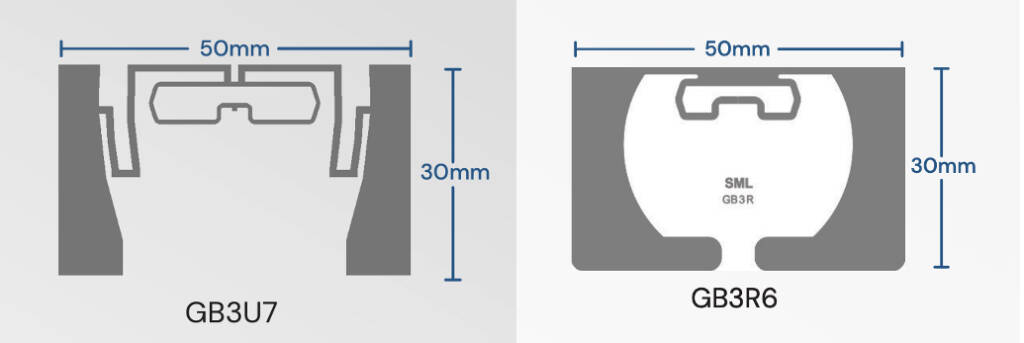

These ARC certification standards, defined by the RFID Lab at Auburn University, ensure that RFID tags “…meet or exceed the levels of performance necessary to provide benefit to both the retailer and the retail supplier in a consistent and cost-effective manner.” Only two tags on the market – SML’s GB3U7 and GB3R6 – pass every single requirement in all 11 categories of the standards.

How to attach RFID tags

As the variety of tags now available has increased, so have the methods of attaching these tags. There are now many creative ways to affix RFID tags that do not alter branding. In some cases, the tags are entirely hidden. Tagging methods vary depending on an item’s shape, size, material, texture, and other environmental conditions. Some of the most commonly used forms of attachment include:

- Adhesive

- Sewn-in

- Hang-on

- Hard tags

The hangtag is one of the most popular methods, and SML has designed inlays specifically for this application. At 50 mm x 30 mm, our GB3 inlays are small enough to be implemented in almost all clothing hang tags or labels typically used worldwide while still being large enough to provide a superior read range.

How to use RFID on difficult-to-tag items

As RFID chips have gotten smaller, they’ve also become more powerful. In the past, RFID inlay antennas needed to be fairly big to provide a long enough read range for shipping verification through dock doors.

Now we have RFID tags that are very small but still have an extremely high read sensitivity. These tags provide optimum tracking performance for densely packed merchandise, a common challenge for inventory management within the retail industry’s RFID systems. RFID tags now on the market have vastly increased the number of items that can be processed, allowing for higher accuracy and faster throughput.

In addition, SML has developed RFID-friendly packaging that has solved the problem of RF interference caused by liquid or metal in specific retail applications. This development means that retailers can now use RFID to accurately track small cosmetic and perfume containers.

SML’s tags and software, combined with our partners’ RFID chips, allow retailers to benefit from RFID inventory tracking without compromising their branding or design. Please check out our How to Choose an RFID Inlay white paper to learn more about our selection of RFID tags.