Clarity® Supply Chain

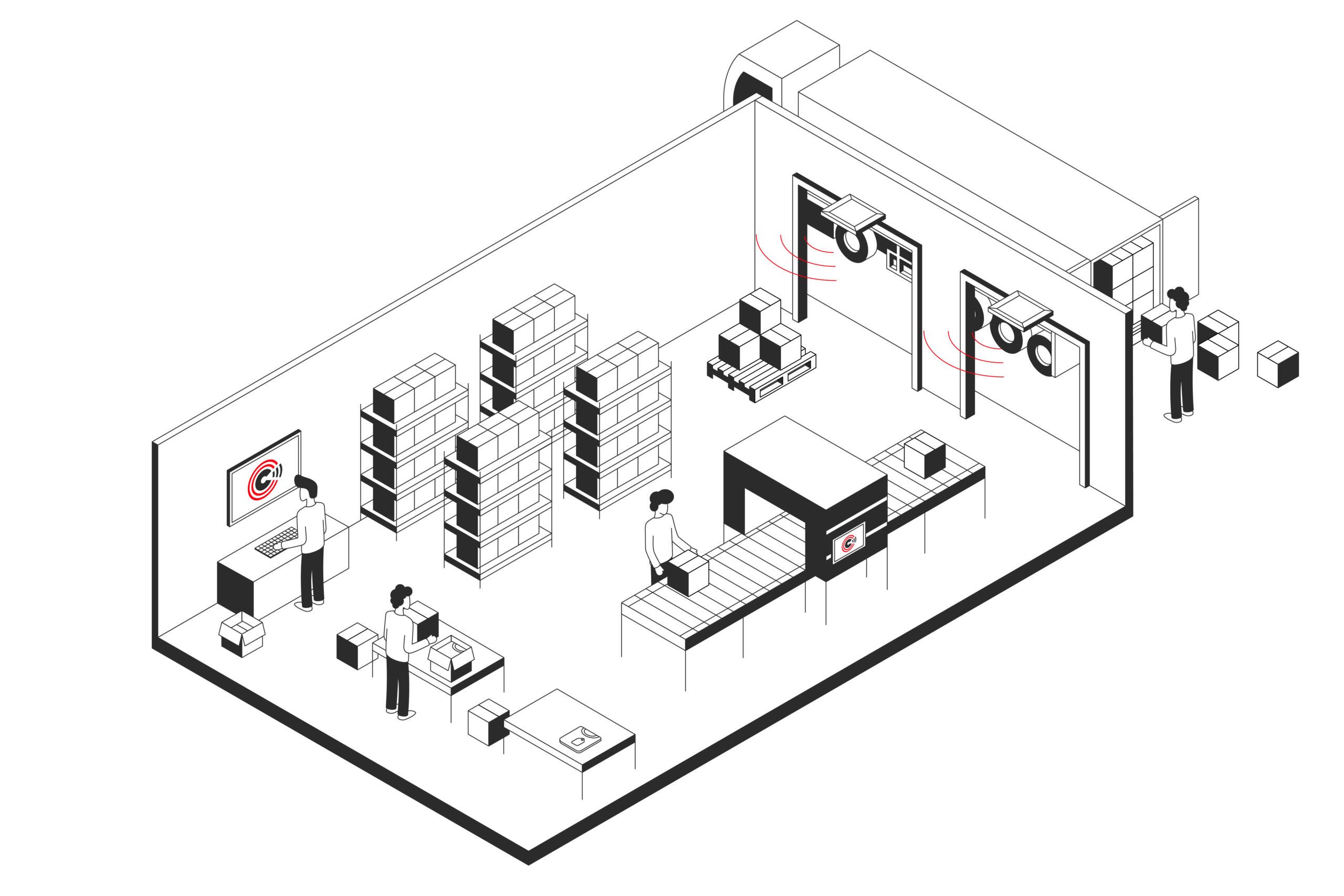

Transitioning from barcodes to item-level RFID enhances enterprise system accuracy in supply chains up to 100%. Clarity® Supply Chain gives visibility into every process step from procurement to delivery, enabling retailers and brands to streamline decision-making and slash operational inefficiencies.

Supply Chain Management Challenges

SML’s State of Retail Insight Report highlights a critical challenge facing retailers: 48% struggle with out-of-stock issues, compounded by a lack of supply chain visibility, affecting sales and business growth. SML’s Clarity® Supply Chain is an industry-first integrated solution with best-in-class enterprise software and subsystems designed to address these problems.

Clarity® Supply Chain Benefits

Automate Inbound Monitoring

RFID Tag Verification

Guarantees vendor compliance and optimal RFID tag quality with correct encoding to ensure accuracy from the start

Automate Auditing

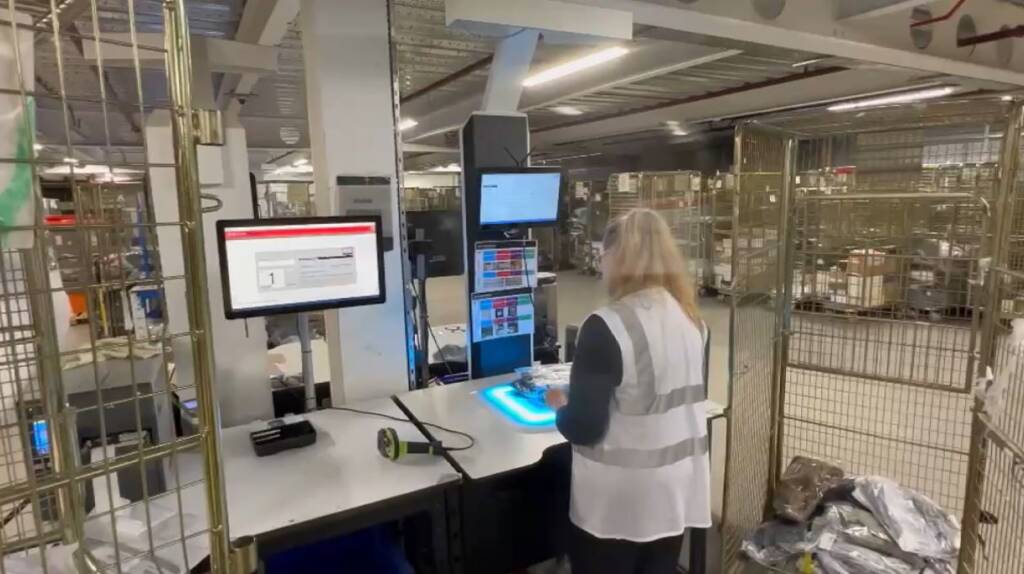

100% accurate automated on-conveyor material handling system and workstation auditing to integrate with every material control process

Streamline Returns Management

Reduce the touches to manage a return by 50% while achieving 100% accurate grading and transaction recording

Business Intelligence

Intuitive reporting on carton/audit results, system uptime, inventory look-up, and more supports informed decision-making

Automate Outbound Monitoring

Efficient Click and Collect

Optimizes order fulfillment: Buy online, collect in-store, cutting wait times and enhancing shopping convenience

Dynamic eCommerce Integration

Enables seamless online sales, enhancing customer reach and digital transaction efficiency

Accurate Packing Audit

100% Audit of packing cartons to verify the picking process matches the order and ensure downstream order compliance

Automate Shipping Verification

100% accurate auditing of outbound shipments driving improved supplier and downstream compliance

Transforming Distribution Center & Factory Inventory Management

Achieve item-level accuracy and efficiency to enhance your supply chain operations.

- Stock Count

- Inbound Receiving/Audit

- Outbound Audit/Shipping Verification

- Automated Carton-level Auditing

- Packing & Picking Audit

- System Uptime

- Inventory Look-up, Search, & Find

Real-World Success

The New Era of Retailing Starts Here with Visible, Agile, Accurate Supply Chain RFID

Creating the foundation you need to empower enterprise-wide transformation from SKU to item-level operations.

100 % RFID auditing during inbound, outbound, and

returns reduces costly mistakes.

RFID creates complete traceability of items throughout the

supply chain.

Vendor compliance reporting reduces customer chargebacks

for accuracy-related charges.

Complete Your Item-Level RFID Transformation

Frequently Asked Questions

What is RFID in supply chain?

RFID in the supply chain refers to the use of Radio-Frequency Identification technology to track and manage the movement of goods from the point of manufacture through to the point of sale and every process in between. It involves attaching RFID tags to the item-level products or at the carton and pallets, which can then be automatically identified and tracked through RFID readers placed at various checkpoints. This technology provides real-time visibility into inventory levels, product locations, and the flow of goods, enhancing supply chain efficiency and accuracy. If you need help getting started, learn more about SML’s Clarity® Supply Chain from our RFID experts.

How does RFID work in logistics?

In logistics, RFID works by electronically storing information on RFID tags, which are then attached to items, pallets, or containers. These tags communicate with RFID readers through radio waves, transmitting data about the tagged items. This enables logistics providers to track and manage the movement of goods in real-time as they move through the supply chain, from warehousing to transportation to delivery, improving operational efficiency and reducing the risk of errors. Learn more about SML’s Clarity® Supply Chain from our RFID experts.

How do you ensure RFID tags are encoded correctly?

Ensuring RFID tags are encoded correctly involves a meticulous process combining industry standards, rigorous quality control measures, and the integration of advanced RFID technologies.

1. Define Encoding Specifications

Start by establishing the specific encoding requirements based on the GS1 EPCglobal standards, which dictate the data structure and format for various types of RFID tags. This includes determining the appropriate EPC (Electronic Product Code) scheme, such as SGTIN (Serialized Global Trade Item Number) for item-level tagging or SSCC (Serial Shipping Container Code) for logistics units.

2. Select Compatible RFID Tags and Equipment

Choose RFID tags that match the quality certification from ARC that are verified and tested for the specific item. Utilize encoding equipment, such as RFID printers or specialized RFID service bureaus, capable of writing to the chosen tag type and complying with the required data protocol.

3. Leverage Specialized Encoding Software

Employ encoding software that supports the desired EPC encoding standards and can generate unique, sequential, or application-specific EPC codes. Software solutions should allow batch processing and enterprise database integration for automated data retrieval and encoding. Typically, RFID tags are encoded during the label or tag printing process.

4. Implement Data Validation and Quality Control

Incorporate data validation steps within the encoding software to check for data accuracy and adherence to the specified EPC format. Conduct quality control checks using RFID readers to verify the correct encoding of each tag. This should include reading the tag data to ensure it matches the intended information and checking for encoding errors or tag failures.

5. Conduct Pilot Testing and Field Validation

Before full deployment, a pilot test with a sample batch of encoded tags in the application environment. This allows for identifying and correcting any encoding issues, tag performance problems, or integration challenges with RFID readers and systems.

6. Train Personnel on Encoding Procedures

Ensure staff responsible for tag encoding are thoroughly trained on the encoding equipment, software, and quality control processes. This includes understanding the technical specifications of the RFID system, common encoding errors, and troubleshooting procedures.

7. Monitor and Optimize the Encoding Process

After deployment, continuously monitor the encoding process for efficiency, accuracy, and error rates. Collect performance data to identify areas for improvement and adjust encoding procedures, equipment settings, or software configurations as necessary to optimize tag encoding quality.

SML’s Clarity® Supply Chain ensures RFID tags are encoded correctly. To learn more, contact one of our RFID experts today.

Can RFID technology help with supply chain challenges like counterfeiting and theft?

Yes, RFID tags can securely store authentication data and track products throughout the supply chain, making verifying authenticity and identifying unauthorized diversions easier. This significantly reduces the risk of counterfeiting and theft. Learn how SML’s Clarity® Supply Chain can help with these challenges. Contact our RFID experts today.

How does Clarity® Supply Chain enhance inventory accuracy?

By leveraging RFID technology, Clarity® Supply Chain enables 100% accurate auditing of inbound and outbound shipments. This precision significantly reduces inventory discrepancies, ensures products are where they need to be, and minimizes lost sales due to stockouts or overstocking. Contact SML’s RFID experts to get started.

Can Clarity® Supply Chain integrate with existing enterprise systems?

Yes, Clarity® Supply Chain is designed to seamlessly integrate with your existing ERP, WMS, and other enterprise systems. This ensures that the real-time data captured by RFID technology enhances your existing processes and provides business intelligence without requiring extensive system overhauls. Contact SML’s RFID experts to get started.

What industries benefit from Clarity® Supply Chain?

While Clarity® Supply Chain is versatile enough for various industries, it finds particular application in retail, apparel, electronics, food, pharmaceuticals, and aviation. Any business seeking to improve supply chain visibility and accuracy can benefit from this solution.

How does Clarity® Supply Chain handle returns management?

The RFID solution streamlines the returns process by enabling 50% fewer touches to manage a return, achieving 100% accurate grading and transaction recording. This efficiency optimizes reverse logistics, saving time and reducing costs. To learn more, contact one of our RFID experts today.

What makes Clarity® Supply Chain different from other RFID solutions?

Clarity® Supply Chain stands out due to its comprehensive yet affordable approach to supply chain management, high accuracy rates, and scalability. It’s backed by SML’s global support and professional services, ensuring successful deployment and maximized ROI. Contact SML’s RFID expert team today.

How can I get started with Clarity® Supply Chain?

To begin transforming your supply chain with Clarity® Supply Chain, contact SML’s RFID expert team. We’ll discuss your specific needs, conduct a detailed assessment, and outline a tailored implementation plan to ensure a smooth integration and quick realization of benefits.