Empowering Supply Chains with Flexible and Factory-Level RFID Solutions

Unlock precision, efficiency, and scalability with Factory Care Solutions (FCS) and In-Plant Printing (IPP) from SML. Designed to streamline factory workflows and enable on-demand RFID printing, these solutions help reduce errors, enhance visibility, and optimize supply chains—whether ensuring factory-level accuracy or enabling flexible RFID printing, we’ve got you covered.

What’s Holding Back Your Supply Chain?

Supply chains are under pressure to deliver faster, more accurately, and at scale. But common challenges may be slowing you down:

Operational Inefficiencies

Accuracy Risks

Visibility Gaps

Scalability Challenges

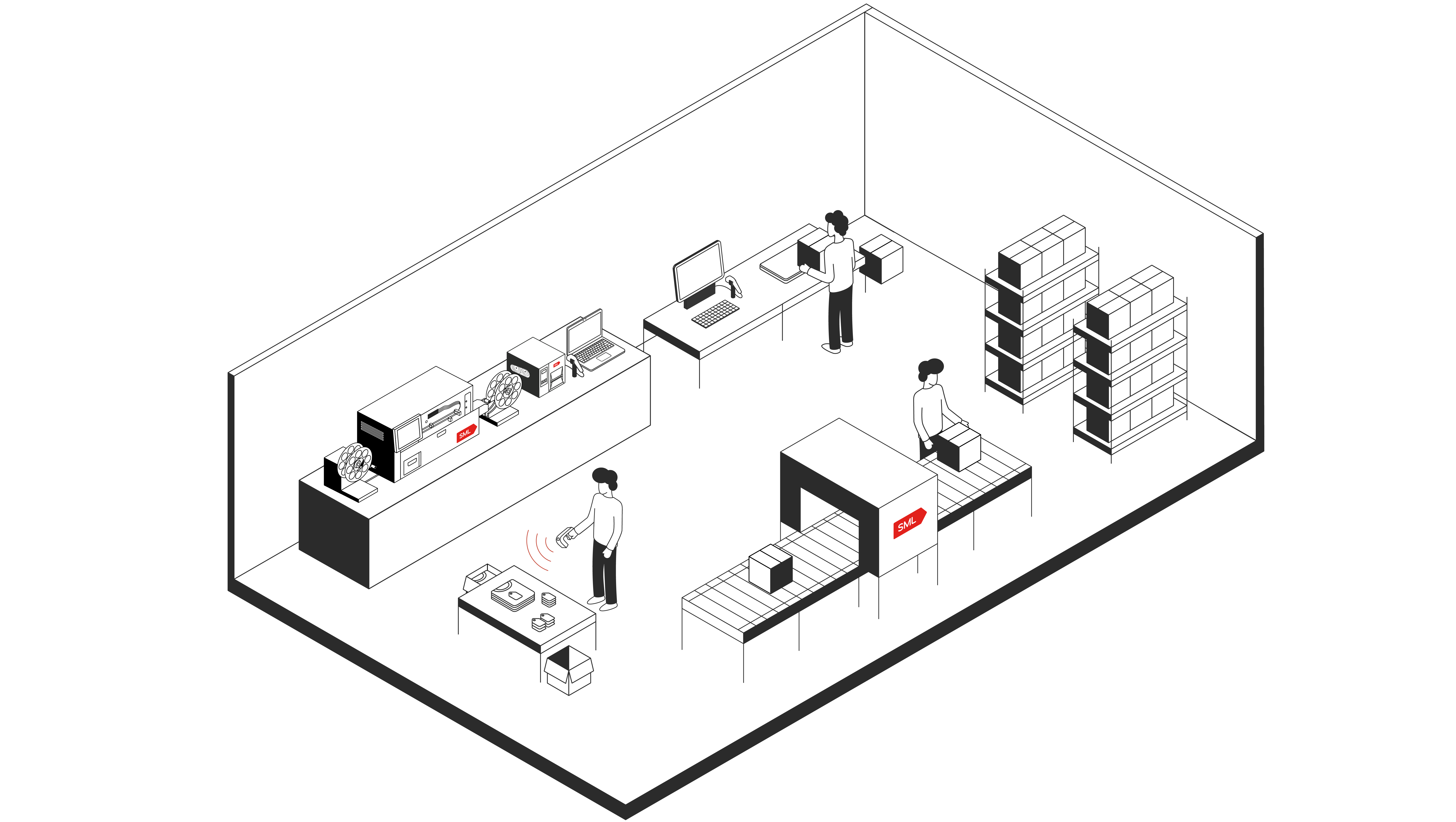

See Factory Care Solutions in Action

How We Solve Your Pain Points with Flexible and Factory-Level RFID Systems

Factory Care Solutions (FCS) and In-Plant Printing (IPP) work together to deliver end-to-end supply chain transformation. Here’s how:

FCS

Tailored for factory environments, ensures precision at the source.

Factory-Based RFID Tagging

Automate and streamline tagging workflows.

Shipment Validation

Validate 100% of shipments for compliance and accuracy.

On-Premise Software

Designed for deployment in factories and attached warehouses.

Manufacturers, factory managers, and supply chain leaders.

RFID Tagging

Automate factory-level tagging to reduce manual errors.

Quality Checks

Ensure all tags are readable and compliant.

Shipping Audits

Validate shipments before they leave the factory.

Eliminate shipment errors and penalties.

Build trust with retailers through consistent, compliant deliveries.

Optimize factory-level workflows for faster production.

IPP

Flexible on-demand RFID printing for rapid replenishment and small-batch production.

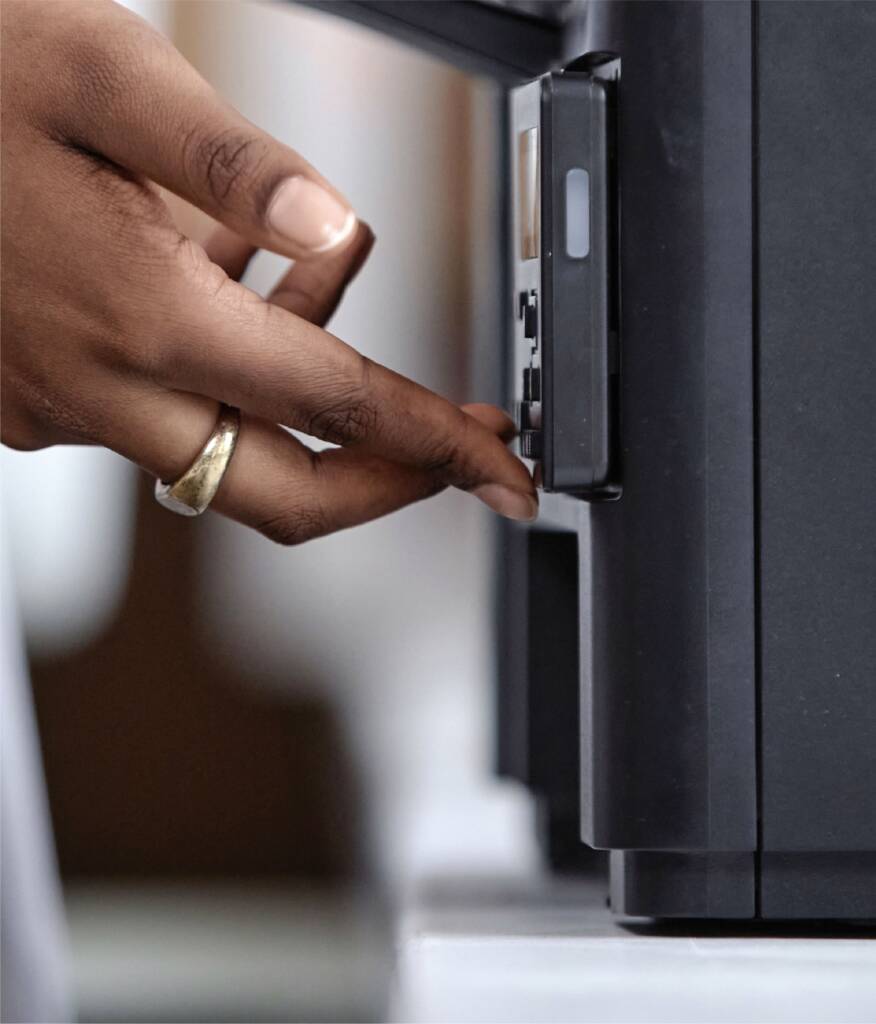

On-Demand RFID Printing

Print small batches of RFID tags whenever and wherever needed.

Location-Agnostic

Deploy in stores, warehouses, or logistics centers.

Flexible Software and Hardware

Adaptable to various use cases and industries.

Logistics teams, retail managers, and operations staff.

Rapid Replenishment

Print tags on-site to meet urgent inventory needs.

Small-Batch Production

Minimize waste by printing only what’s needed.

Compliance Validation

Ensure every tag meets retailer standards.

Reduce lead times and transportation costs with localized tag production.

Stay agile during peak demand periods with rapid printing capabilities.

Minimize waste through efficient, on-demand production.

Testimonial

Real-World Success Stories

How are these challenges impacting your operations?

Sustainability Through Innovation

Our RFID solutions are designed with sustainability in mind, helping you achieve your ESG goals while optimizing your supply chain.

0%

Reduction in Material Waste

0%

Energy Savings

0%

Traceability

Your Challenges, Solved.

| Pain Points | Solutions |

|---|---|

| Shipment Errors | Real-Time Dashboards |

| Manual Processes | Manual Processes |

| Lack of Visibility | Flexibility to Adapt |

Powerful Features to Streamline Your Operations

Why Choose SML?

Trusted Expertise:

Over 20 years of RFID leadership, trusted by global brands.

Global Reach, Local Support:

Operations in 20+ countries with 40+ service bureaus for on-ground assistance.

Flexible, Scalable Solutions:

Tailored for factories, distribution centers, and retail operations

of all sizes.

Proven Results:

95% improvement in shipment accuracy, 40% reduction in production delays, and 30% faster turnaround times.

Ready to Transform Your Supply Chain?

Speak with our experts to find out how Factory Care Solutions fits your needs.